INSTALLATION

Packing materials. All packing materials should be removed from the valve connections before to installation (plastics caps and lever wires). Fit the connecting gaskets and put the safety valve in position.

Set Pressure. Check that the set pressure on the nameplate is as required.

Back pressure. Check the nameplate to determine if the valve was already set with a correction for backpressure. Verify the maximum value of back pressure and/or consult to TOSACA.

Lever. Do not use the lifting lever to hoist the valve during installation.

Test gag. Remove test gag before to test set pressure.

Spindle vertical. Spring loaded safety and safety relief valves should be installed in the upright position with vertical spindle.

System cleaning. The vessel and piping must be clean and free from any foreign matter before installing the safety valve. Clean the flange on which the valve is to be installed using an appropriate solvent.

Discharge lines. Discharge lines from safety relief valves shall be at least the same size as the valve outlet and as short and direct as possible. The valve body drain and vent holes must not be plugged. Never reduce the inlet or outlet pipe connections to the safety relief valve. Adequately supported discharge piping relieves stress on the safety relief valves.

Teflon. The use of Teflon impregnated pipe compound and Teflon tape on pipe threads provides lubricity which can lead to overtightening and breakage. Do not overtighten. Failure to follow these instructions could result in property damage and/or moderate personal injury.

Painting. If the safety relief valves will be paint, care must be taken to protect the lever, open bonnet and identification plate.

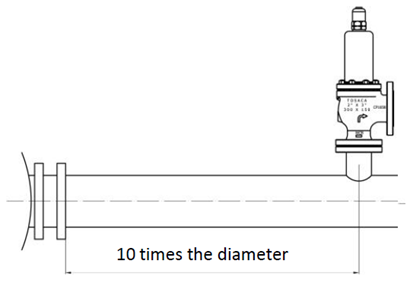

Turbulences. Not less than 10 pipe diameters from any device that causes turbulences.